During the routine maintenance of a section of the contact network of the Beijing-Shanghai High-Speed Railway, engineers found a batch of special "small objects" that were more than 10 years old - plastic cable ties. These seemingly ordinary white straps of plastic cable ties are still firmly fixed after long-term exposure to wind, sun, rain and snow, and their insulation performance and mechanical strength have not weakened. This discovery amazed the on-site technicians.

This plastic cable ties has changed the way cables are fixed in the field of electrical engineering. Compared with traditional metal cable ties, its advantage lies in its excellent insulation performance. Since plastic itself is an insulating material, this plastic cable tie fully meets the safety requirements under high-voltage environments. "Under the high-voltage environment of 27.5kV of the contact network, the plastic cable tie is like a reliable insulation barrier, effectively blocking the risk of leakage." Zhang Gong, a technical engineer of China Railway Electrification Bureau, commented.

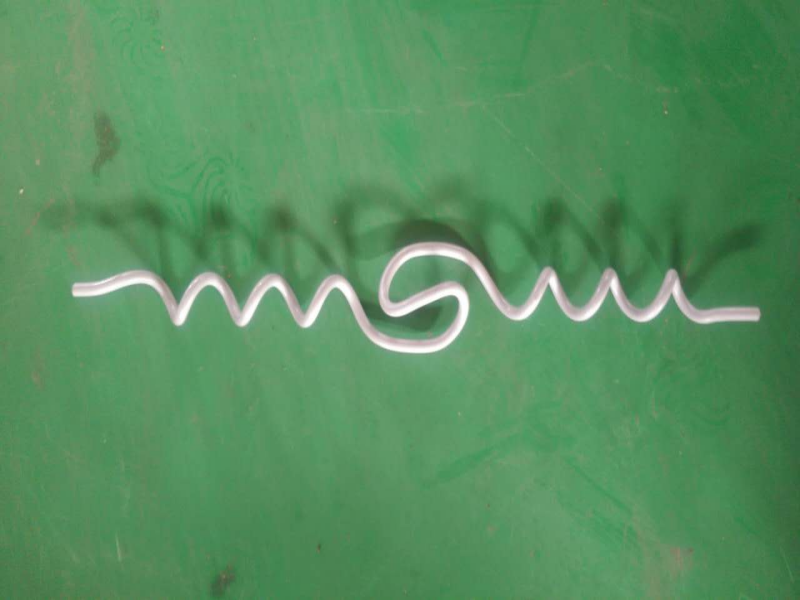

In addition to plastic cable tie excellent insulation performance, the plastic single-angle edge cable tie is also favored by engineers because it is lighter than traditional binding wires. A single cable tie weighs only 3.2 grams, less than one-fifth of a metal cable tie. The Shanghai Metro maintenance team has made precise calculations: if all the wiring harnesses in a subway car are fixed with this type of plastic cable tie, the overall weight can be reduced by 4.7 kilograms. "Especially when working at high altitudes, our maintenance personnel can easily carry hundreds of cable ties, which greatly improves work efficiency." said Master Wang, the person in charge of subway maintenance.

The operation and maintenance records of an offshore wind farm show that after experiencing multiple typhoons, the cables fixed with plastic single-angle edge cable ties remain intact. "Its single-angle lock design is very clever. When the cable swings in strong winds, the cable tie will become tighter and tighter." Wind power technician Xiao Li pointed to the wiring harness in the cabin and said. The comparative test data is more convincing: under the same sunshine conditions, ordinary nylon cable ties will become powdery in 2 years, while the tensile strength of this plastic single-angle edge cable ties can still maintain the initial value after 5 years.

With the continuous advancement of technology, the application field of plastic single-angle edge cable ties continues to expand. At present, the PVC cable tie clips produced by our company have passed many authoritative certifications such as railway product certification and environmental protection testing. From high-speed rail contact networks to household distribution boxes, from 5G base stations to agricultural greenhouses, plastic single-angle edge ties are protecting line safety in various fields with their unique advantages. As an electrical engineer said: "In electrical engineering, it is often these seemingly inconspicuous small accessories that determine the reliability and safety of the entire system." This inconspicuous but crucial "small object" is proving with its actual performance that details can also determine success or failure in modern engineering construction.