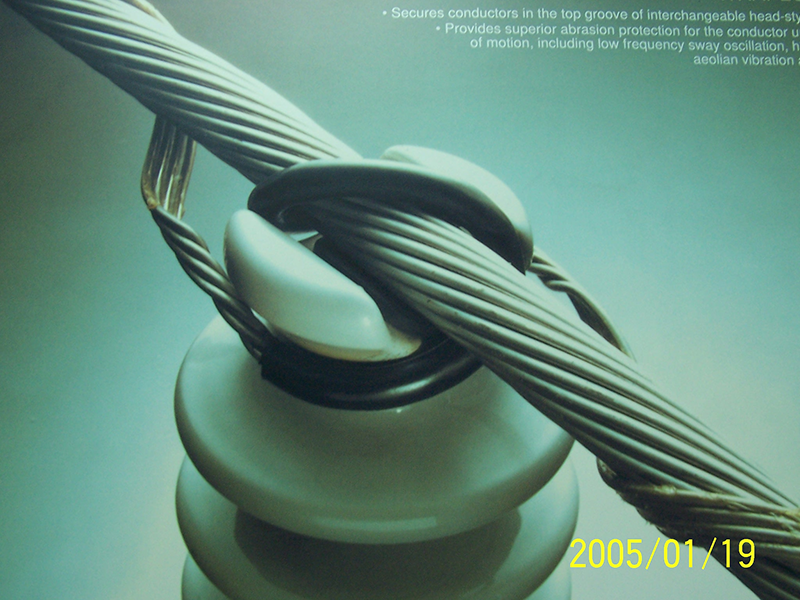

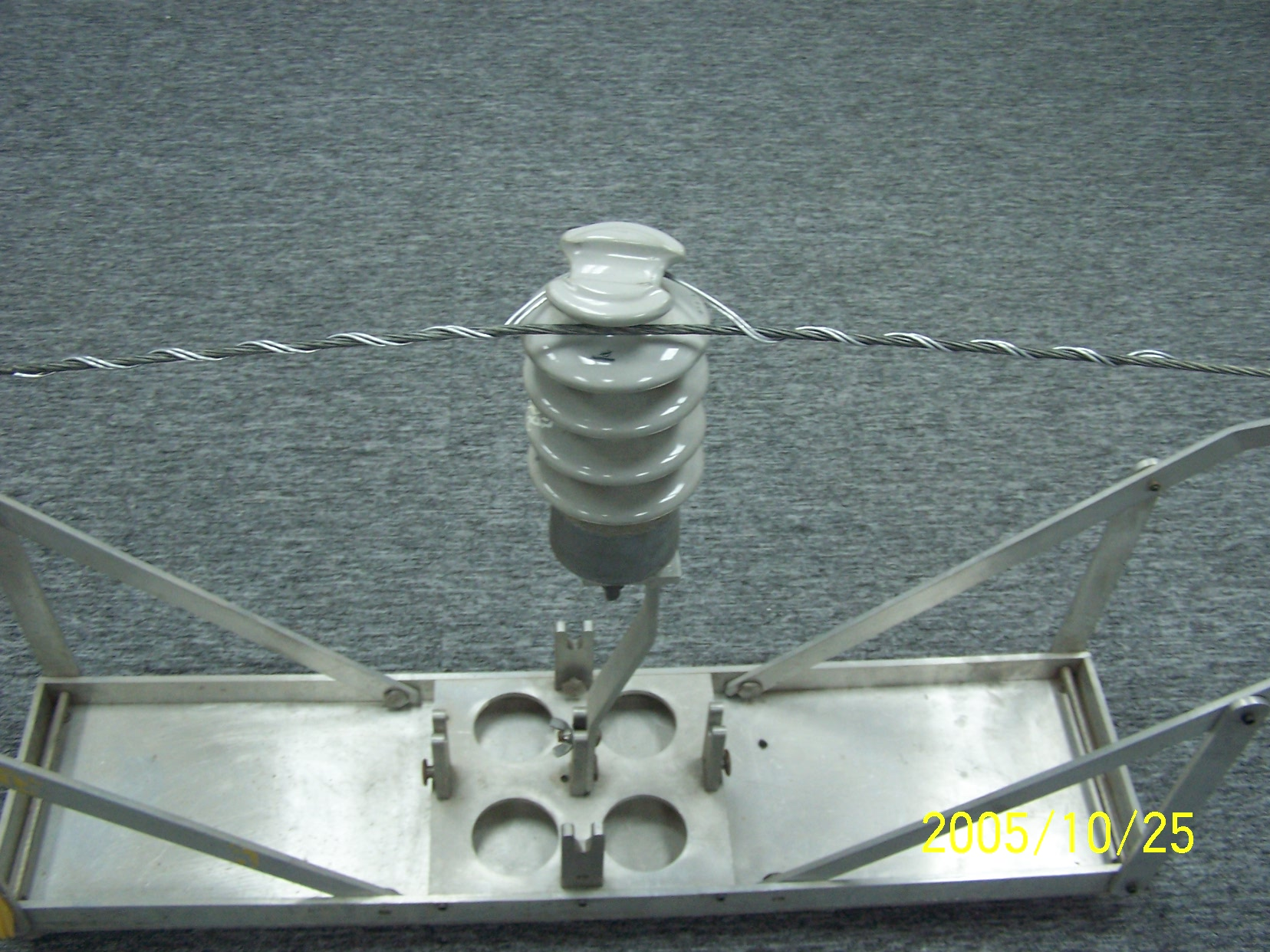

Preformed Tie Wire is a cable assembly prefabricated in a specific spiral shape by multiple strands of metal wire or composite materials. It is used for overhead power conductors and power overhead optical cable terminals, suspensions, joints, etc. It does not need to be twisted on site and can be directly installed. At present, Preformed Tie Wire is often used in power transmission and distribution, optical fiber communications, electrified railways, cable TV, construction, agriculture and other fields.

The main difference between Preformed Tie Wire and traditional hardware is reflected in materials, structure, installation method and performance characteristics. Traditional hardware is usually made of cast iron, forged steel or aluminum alloy, and is made by casting or machining. Bolt tightening, crimping or welding are often required during installation. The construction process is complicated and may cause mechanical damage to the wire. Preformed Tie Wire uses high-strength aluminum alloy wire or composite materials, which are pre-formed by a precisely designed spiral structure. It can fit tightly on the surface of the wire, is easy to install, and does not require special tools, which greatly reduces the difficulty of installation and the risk of damage to the wire.

In terms of performance, traditional hardware is prone to metal fatigue or corrosion due to stress concentration during long-term operation due to its rigid structure, especially in some extreme environments, such as coastal high salt fog areas or industrial pollution areas, its durability may be affected. In contrast, the flexible structure of Preformed Tie Wire can evenly distribute mechanical loads and reduce stress concentration. At the same time, its materials usually have good corrosion resistance, so it performs better in fatigue resistance, vibration resistance and weather resistance. In addition, the non-destructive installation method of Preformed Tie Wire makes it particularly suitable for repairing or upgrading old lines, while traditional hardware may cause secondary damage to the wires during disassembly and replacement.

From the perspective of application scope, traditional hardware still dominates in ultra-high voltage transmission lines and large-span projects because traditional hardware has stronger load-bearing capacity and more stable structure. Preformed Tie Wire has more advantages in the fields of medium and low voltage distribution lines and electrified railway contact networks, especially in occasions where frequent installation or maintenance is required, the convenience and reliability of Preformed Tie Wire are more important.

We always adhere to high standards and high investment, and use world-class production equipment to ensure product quality. At the same time, we will conduct a full range of quality inspections before the products leave the factory to ensure that each product meets the quality assurance system. If you have any consultation or purchase needs, please contact us.