There are many factors that affect the Grounding Wire Clamp in electrical safety, such as the conductivity and corrosion resistance of the Grounding Wire Clamp material, the cross-sectional area, etc. Generally speaking, commonly used grounding materials include copper, aluminum, and steel. Copper has good conductivity and corrosion resistance, but the cost is high. The conductivity of aluminum is slightly inferior to copper, but its price is relatively low. In practical applications, it is necessary to select suitable grounding materials according to specific environments and requirements. In addition to considering the conductivity and corrosion resistance of the material, it is also necessary to pay attention to its cross-sectional area. A cross-sectional area that is too small will increase resistance and affect the grounding effect. According to relevant standards and specifications, the cross-sectional area of Grounding Wire Clamps of different uses and current sizes has clear requirements. Among these influencing factors, people often ignore that the length of the Grounding Wire Clamp will also affect electrical safety. Let's talk about it next.

Grounding Wire Clamps that are too long or too short will bury safety hazards. If the Grounding Wire Clamp is too long, the resistance and inductance of the wire itself will increase significantly. When the equipment leaks electricity, the fault current may not be able to be discharged quickly, causing the protection switch to delay tripping. A too long Preformed Grounding Wire will produce a large voltage drop in the fault state, which may cause the equipment casing to be accidentally charged, increasing the risk of electric shock. In addition, a Preformed Grounding Wire that is too long can easily entangle the equipment or trip the staff, and it may cause a short circuit after the outer skin is worn.

On the other hand, a Preformed Grounding Wire that is too short is not good either. A Preformed Grounding Wire that is not long enough is easily pulled when the equipment is running, which may cause the joint to loosen or even break over time. When a lightning short circuit occurs, a Preformed Grounding Wire that is too short will cause the fault current to be concentrated in a very small range, forming a dangerous voltage difference on the ground, and a step voltage may be generated between the two feet when people pass by. Therefore, the Preformed Grounding Wire cannot be shortened casually for the sake of convenience, nor can it be too long for convenience. The appropriate length must be selected according to the specifications.

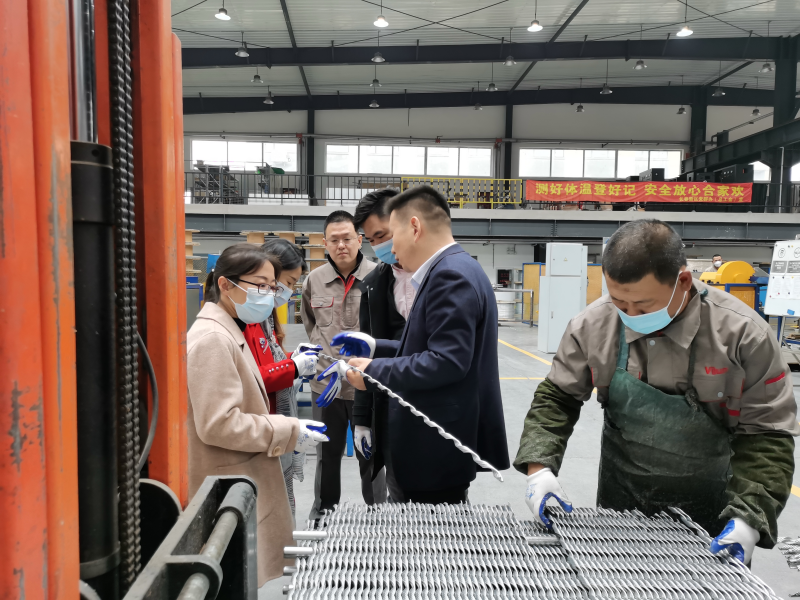

Therefore, during the design and construction process, we must strictly follow the standards to select the appropriate length of the grounding wire to ensure that the grounding system can effectively introduce the fault current into the earth and ensure the safety of personnel and equipment. The length, specifications and materials of the grounding wires produced by our company can be flexibly adjusted according to the needs of the project to meet your needs.