Vibration damper introduction:

Vibration damper is a shock-absorbing device widely used in industrial equipment and mechanical systems, designed to suppress vibrations generated during equipment operation. Vibration damper absorbs and reduces vibrations and shocks in mechanical movement, effectively improving equipment stability, extending service life, and reducing noise. Vibration damper is suitable for various mechanical equipment, construction, transportation tools and other scenarios, and is widely used in mining, metallurgy, construction, automobile and other industries.

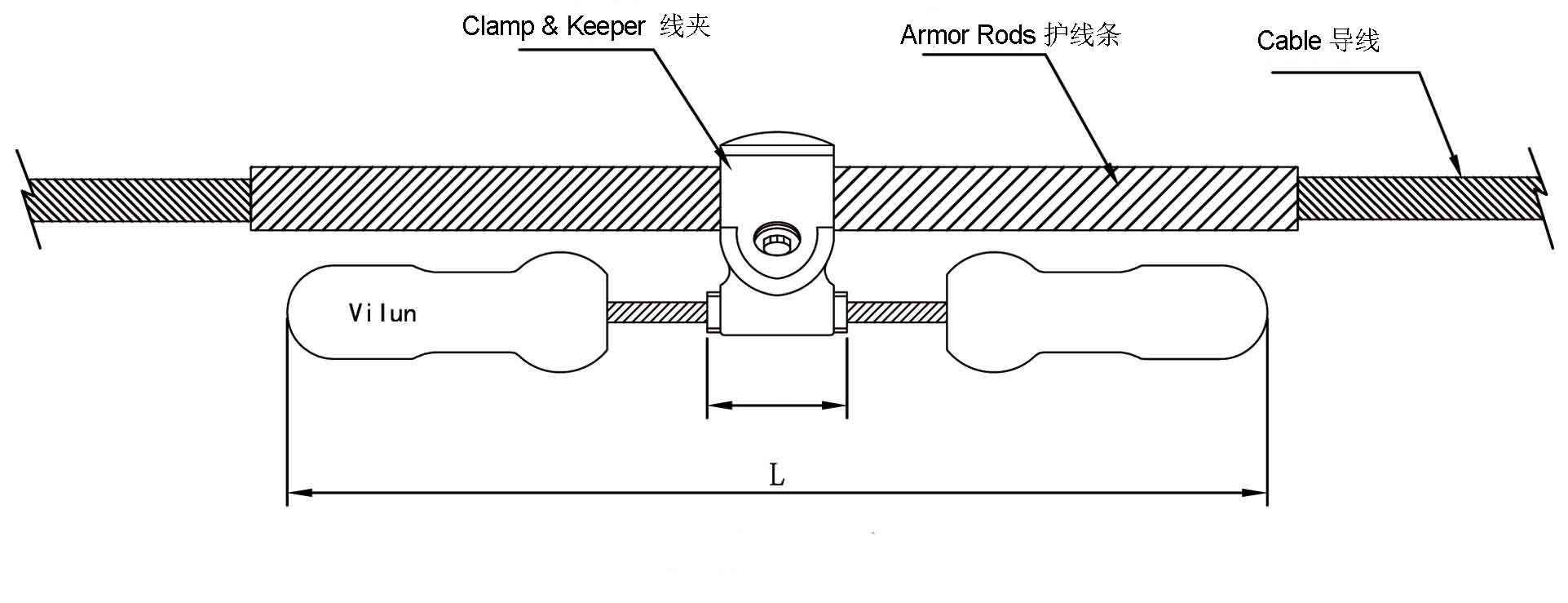

Features of shock-absorbing hammer protective rod:

The Shock-absorbing hammer protective rod has been specially designed and processed to have excellent anti-fatigue performance and can maintain a stable protective effect during long-term operation. The Shock-absorbing hammer protective rod can effectively reduce the noise pollution caused by equipment vibration and create a comfortable working environment by absorbing and converting vibration energy. The Shock-absorbing hammer protective rod is made of high-quality anti-vibration materials and can effectively suppress the vibration and impact of mechanical equipment through precise design to ensure the stable operation of the equipment. The Shock-absorbing hammer protective rod has improved the energy absorption and conversion efficiency through optimized design, which can significantly reduce the energy consumption of equipment, improve energy utilization efficiency, and meet green environmental protection standards.

Working principle of preformed vibration damper:

Based on the principle of vibration and energy dissipation, Preformed vibration damper reduces the vibration and dancing damage caused by wind, ice and other meteorological conditions to overhead power lines through unique design. Preformed vibration damper consists of steel strands, weights and clamps. When the conductor vibrates, Preformed vibration damper vibrates with the conductor, consumes vibration energy through the bending movement of steel strands, and dissipates it by converting it into heat energy, sound energy, etc. At the same time, Preformed vibration damper also produces a movement in the opposite phase to the conductor vibration, further reducing the vibration. On high-voltage overhead lines, anti-vibration hammers are selected and configured according to the actual situation of the line and the vibration characteristics to ensure the best protection effect.

Application of vibration damper:

1. Power field:

The application of vibration damper in the power field is mainly to reduce the vibration and dancing damage of overhead power lines. By installing it near the wire clamp of the hanging conductor, the vibration damper can effectively absorb and dissipate the vibration energy of the conductor and generate a movement that is opposite to the phase of the conductor vibration, thereby reducing the vibration amplitude of the conductor.

2. Communication field:

In the communication field, vibration damper also plays an important role. The communication line has a low tolerance for vibration. Vibration may cause the optical fiber inside the optical cable to break or signal attenuation, thereby affecting the communication quality. By installing an anti-vibration hammer on the communication line, the vibration amplitude of the line can be effectively reduced, and sensitive lines such as optical cables can be protected from vibration damage.

3. Wind power generation field:

The blades of wind turbines will be affected by wind force and their own vibrations during rotation. These vibrations will damage the blades and reduce the power generation efficiency. By installing vibration damper on the blades, the power generation efficiency and stability of wind turbines can be greatly improved, and the service life of the blades can be extended.

Our factory:

Our company's product processing plant is large in scale, with multiple production workshops in the factory. The production of products covers every link from material cutting, welding to testing. Each link is tested by a professional technical team to ensure the quality of the products. Our R&D team is composed of experienced engineers, committed to innovative research and development, constantly optimizing product design and improving product performance to meet customer needs. At the same time, we have a special quality inspection department to inspect the products before they leave the factory. From the selection of raw materials to the final inspection of the finished product, each process is strictly carried out in accordance with product safety standards.