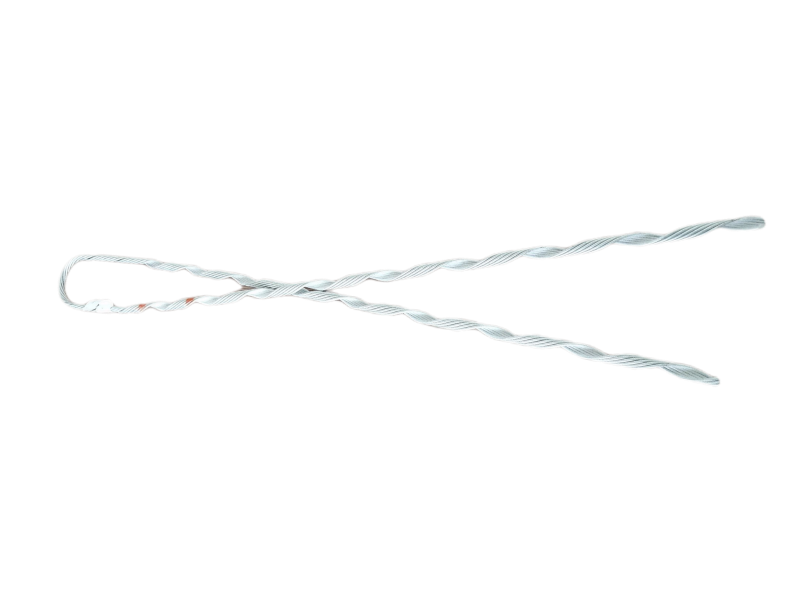

As a commonly used connection fastening component in power and communication lines, rope tightening clamp has the advantages of stable structure, easy installation, and uniform force. It is widely used in wire fixing, jumper connection, terminal fastening and other scenarios. The correct use of rope tightening clamp can not only ensure the safety of line operation, but also extend the service life of equipment. This article will introduce you in detail the correct use and installation method of the clamp.

The correct use of rope tightening clamp requires preliminary preparations, including model and specification verification, material quality inspection, and tool preparation. The model of rope tightening clamp needs to strictly match the material, diameter, and force requirements of the fastened wire. Before use, it is necessary to confirm the applicable wire range, rated load and structure type identified by the clamp to prevent fastening failure or wire damage due to inconsistent models. It is also necessary to check the appearance of the clamp for cracks, deformation, rust and other defects. The surface of the preformed wire should be smooth and burr-free, and the coating should be uniform and complete. At the same time, check the product certificate and factory inspection report to ensure that the clamp material meets industry standards and avoid the use of inferior or expired products. The preparation of installation tools includes cleaning tools such as rags and sandpaper, measuring tools such as vernier calipers and tape measures, auxiliary tools such as rubber hammers and torque wrenches, and safety tools such as insulated gloves and helmets.

In the process of installing the rope tightening clamp, the operation should be standardized for good fastening effect. During the pretreatment of the wire, the surface must first be cleaned, and the position of the wire to be installed should be wiped with a rag to remove oil and dust. If there is an oxide layer on the surface of the wire, it needs to be gently polished with sandpaper to reveal a metallic luster, so that the clamp fits closely with the wire to prevent local heat caused by poor contact. Then mark the position. According to the design requirements, mark the starting and ending points of the clamp installation with a marker pen on the wire, so that the clamp is installed in the center and the force is uniform.

At the beginning of the installation of the clamp, the preformed wire should be positioned, and the spiral preformed wire of the rope tightening clamp should be wound on the wire in a clockwise direction or in the direction specified by the product from the marked starting point. When winding, it is necessary to keep the preformed wire flat, so that each circle of preformed wire closely fits the wire, and there is no loose gap. Then tighten gradually, gently push the preformed wire by hand to a natural fit. If you encounter resistance, you can use a rubber hammer to tap the end of the clamp axially to assist the preformed wire in place. Finally, check the fit. After the installation is complete, shake the clamp by hand to confirm that it is not loose, and then observe the fit between the preformed wire and the wire, so that all the spiral rings are in close contact, and there is no partial cocking or gap.

Do you understand the use and installation of rope tightening clamp? Vilun Electric Co., Ltd. always provides customers with first-class products and fine service. Our products have been sold to Europe, America, Asia, Africa, Oceania and other countries. If you are interested in learning about our products, please feel free to contact us!