In the material management of electric power, communications, construction and other industries, the cable storage bracket provides a systematic solution for the storage, storage and turnover of cables, and is an indispensable special equipment. Whether it is temporary storage in engineering construction or long-term storage in warehouses, the cable storage bracket plays an important role in protecting cable performance, improving space utilization, and ensuring operation safety. It is an important auxiliary component in the whole life cycle management of cables.

The function of the cable storage bracket is to provide a stable and orderly storage environment for cables, so the design of the bracket needs to take into account safety, practicality and economy at the same time. From the point of view of safety, a high-quality cable storage bracket can avoid damage to the cable due to extrusion, bending or moisture. For example, if a high-voltage cable is stacked and pressurized for a long time, it may cause damage to the insulation layer and leave safety hazards. The layered design of the bracket allows each roll of cable to be placed independently, reducing the risk of physical damage. In terms of practicality, the height and layer spacing of the bracket can usually be adjusted according to the cable specifications to adapt to cables of different diameters and lengths. Economically, the rational use of brackets can reduce the waste caused by improper storage of cables, extend the service life of cables, and indirectly reduce engineering costs.

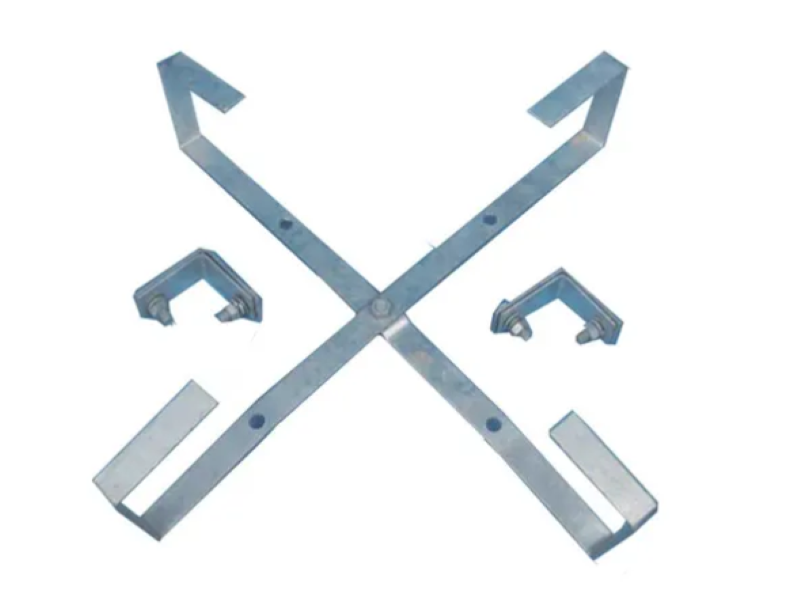

From the point of view of structure type, cable storage bracket can be divided into three categories: fixed, mobile and foldable, each suitable for different scenarios. The fixed bracket consists of a metal frame and a load-bearing layer, which is bolted to the ground or wall. It has strong load-bearing capacity and high stability. It is suitable for long-term storage of heavy cables in large warehouses. The advantage of the fixed bracket is that it can make full use of vertical space and reduce ground occupation, especially suitable for places with many types of cables and large storage capacity. The mobile bracket is equipped with a universal wheel and a brake device at the bottom, which has a storage function and mobility flexibility. It is commonly used in construction sites or scenes where the storage location needs to be adjusted frequently. The foldable bracket adopts a foldable structure, which can be folded for storage when idle, saving storage space, and is suitable for small and medium-sized engineering teams or temporary storage needs.

In terms of material selection, the cable storage bracket needs to meet the requirements of load-bearing, anti-corrosion, and durability. Common materials include carbon steel, stainless steel, and aluminum alloy. The carbon steel bracket is formed by welding or bolting, which has a low cost and good load-bearing performance, but it needs to be painted or galvanized to prevent rust, and it is suitable for dry environments. Stainless steel brackets have excellent anticorrosive properties, can adapt to humid and dusty outdoor environments, and have a long service life, but the cost is relatively high. They are commonly used in occasions with high environmental adaptability requirements. The aluminum alloy bracket is light in weight, high in strength, and has anti-corrosion properties. It does not require additional treatment. At the same time, it has good heat dissipation, which can reduce heat accumulation during cable storage, and is suitable for storing high-voltage cables that require heat dissipation.

In short, the cable storage bracket can protect cables, save space, and facilitate transportation. It is an important equipment to ensure the safety of cable storage and improve management efficiency. In the fields of power engineering, communication construction, etc., choosing the right cable storage bracket can not only reduce material loss, but also provide basic guarantees for construction safety and project quality.