The main purpose of electrical grounding is to ensure the safety of personnel. When electrical equipment fails, such as when the insulating layer is damaged and the charged part is exposed, the grounding system can quickly introduce the fault current into the ground. If the equipment is not grounded, once the human body comes into contact with the live shell, the fault current will form a circuit through the human body, causing a serious electric shock accident. The perfect grounding system can greatly reduce the voltage of the equipment housing, so that the fault current flows into the ground through the low-resistance preformed grounding wire first, so as to control the contact voltage within a safe range, effectively avoiding casualties. According to statistics from the International Electrotechnical Commission, standardized grounding measures can reduce the incidence of electric shock accidents related to electrical equipment by more than 90%.

The purpose of electrical grounding is also to protect equipment. Transient high voltages such as lightning strikes and operating overvoltage can cause damage to the insulation of electrical equipment. Through the grounding device, these instantaneous high-energy electric charges can be quickly discharged to the ground to prevent excessive induced voltage from being generated inside the equipment. For example, in a substation, the combination of lightning rods and grounding nets can quickly disperse the lightning strike current, protect important equipment such as transformers and circuit breakers from surge shocks, extend the service life of equipment, and reduce production interruptions and high maintenance costs caused by equipment damage.

In addition, electrical grounding plays an important role in maintaining the stable operation of the system. In a three-phase AC system, neutral ground can balance the three-phase voltage and prevent voltage offset caused by unbalanced three-phase loads. A stable grounding system can effectively suppress harmonic interference in the power system and improve power quality. This is very important for data centers and precision electronic equipment manufacturing workshops with extremely high voltage stability requirements. At the same time, good grounding measures can help reduce electromagnetic interference, allow communication equipment and control systems to operate normally, and avoid production accidents or data loss caused by signal disturbances.

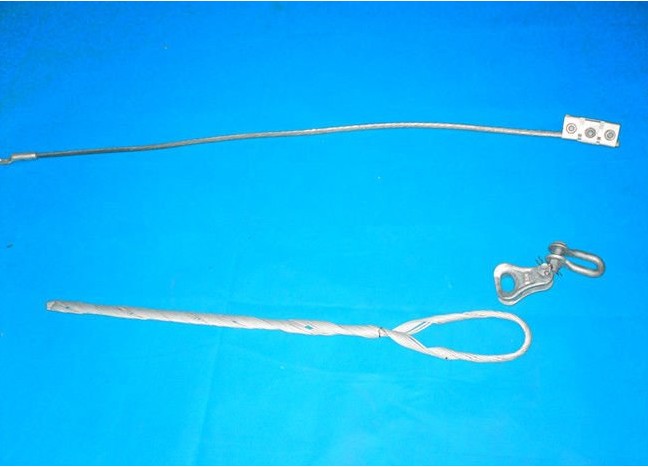

For buyers, choosing a high-quality preformed grounding wire is the basis for achieving the above electrical grounding purposes. High-quality preformed grounding wire has low resistance, high mechanical strength and excellent corrosion resistance, which can allow the grounding system to work stably for a long time in harsh environments. Our company has been deeply engaged in the power field for many years and can provide customers around the world with preformed grounding wire solutions that meet strict standards.

Our preformed grounding wire is made of corrosion-resistant materials. After special processing, the conductor resistivity is much lower than international standards, which can ensure the rapid discharge of fault current.In terms of extreme environmental adaptability, the preformed grounding wire has passed a number of rigorous experiments such as salt spray test and high and low temperature cycle test. No matter what the scene and environment, the preformed grounding wire can maintain stable performance. If you still want to know more product information or customized solutions, please feel free to contact us, we will provide you with detailed technical support and services.