Preformed vibration dampers have become essential parts of vibration reduction solutions across various industries for effective vibration mitigation in industrial equipment and mechanical systems. Their unique hammerhead/line clamp connection disperses vibration energy efficiently, improving equipment stability while lengthening service life extenders while simultaneously decreasing noise pollution levels.

Preformed vibration dampers are protected with a protective coating to avoid moisture or corrosion damage and ensure long-term and stable performance. Their unique design allows them to absorb vibration energy for absorption purposes as well as significantly decreasing energy use while meeting environmental standards.

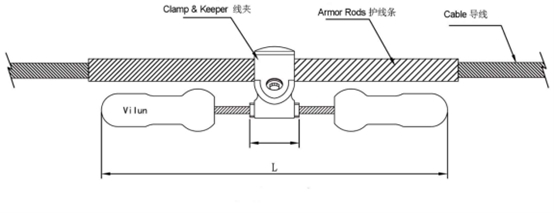

Preformed vibration dampers work through dissipating vibration and energy dissipation. Composed of steel strand, weight, and line clamp, when an object vibrates it causes the damper to move with it; its bending motion then dissipates vibration energy transforming it to heat or sound energy and further reducing vibration amplitudes while protecting equipment against damage. Particularly useful in high voltage overhead lines where preformed vibration dampers can be tailored specifically according to line conditions and vibration characteristics for optimal protective effects.

Preformed vibration dampers are widely used in power transmission, railway systems, and industrial machinery to enhance structural integrity and operational safety. Their ability to minimize oscillations and reduce fatigue stress makes them crucial components in extending the lifespan of cables, conductors, and other mechanical structures subjected to continuous dynamic forces.

In high-voltage overhead lines, these dampers effectively mitigate aeolian vibration, which occurs due to wind-induced oscillations. By preventing excessive conductor movement, they help reduce wear at suspension points and decrease the risk of mechanical failure. Additionally, preformed vibration dampers can be designed with different weight configurations to accommodate various cable diameters and tension levels, ensuring precise damping performance.

Beyond the energy sector, preformed vibration dampers are also applied in bridge cables, industrial pipelines, and mechanical structures where controlling vibrations is critical to maintaining structural stability. Their durable construction, resistance to extreme weather conditions, and low maintenance requirements make them a cost-effective solution for long-term vibration control.

With ongoing advancements in materials and design, modern preformed vibration dampers offer improved energy dissipation efficiency and enhanced adaptability to diverse operational environments. By integrating these dampers into vibration control strategies, industries can achieve greater equipment reliability, reduced maintenance costs, and improved safety standards while aligning with environmental sustainability goals.